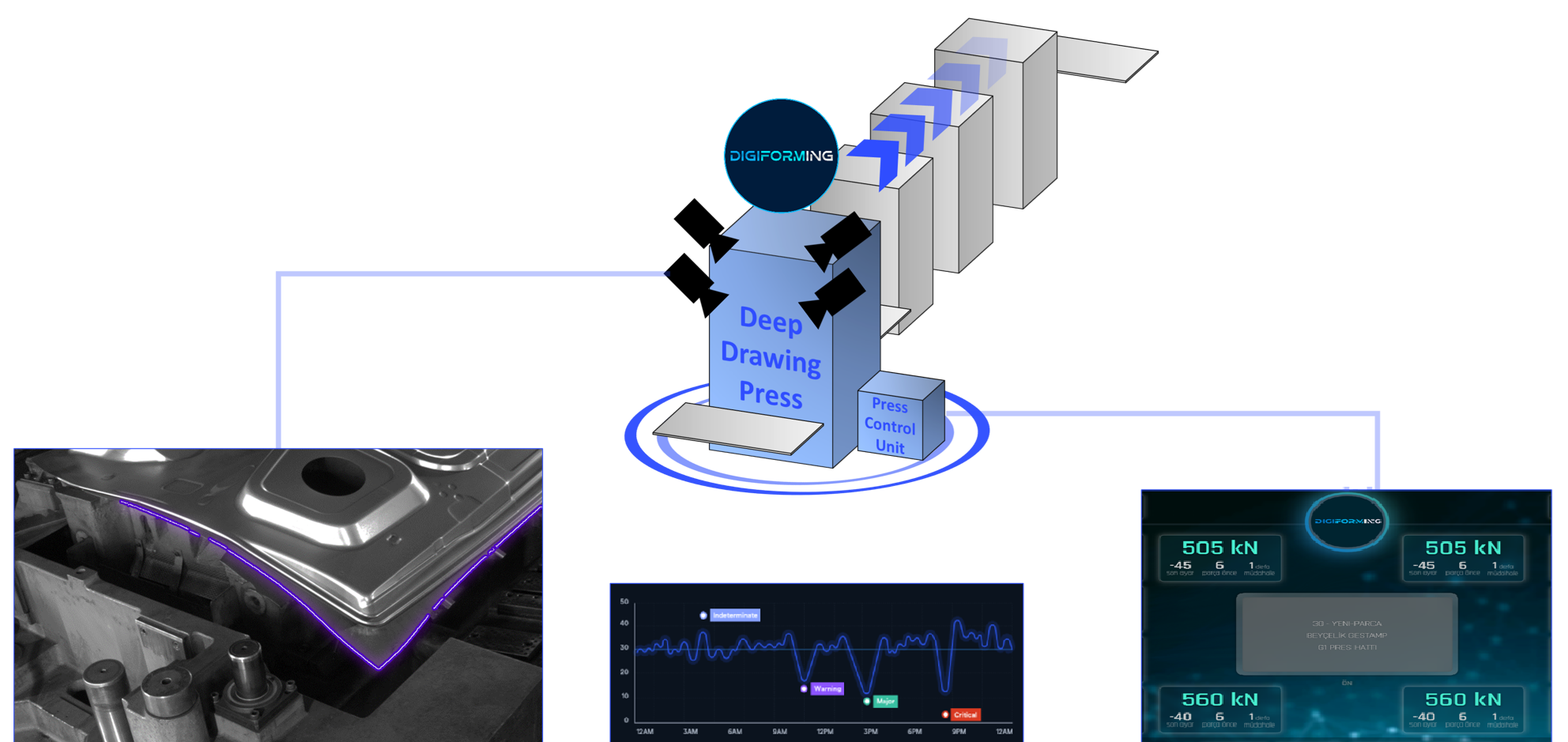

Digiforming Defect Prevention

Our AI-powered solution prevents costly defects before they happen by continuously optimizing deep drawing processes in real time. It helps manufacturers boost quality, reduce downtime and maximize profitability.

Stamping Excellence on Your Press Line

Massively Reduces Scrap

Prevents 80–100% of scrap, significantly reducing material waste and increasing sustainability on the press line.

Boosts Production Efficiency

Increases operational efficiency by 3–5% by stabilizing the production process and minimizing interruptions due to quality issues.

Real-Time Defect Prevention

The system monitors the deep-drawing process in real time and adjusts press parameters automatically to prevent defects like tearing, wrinkling and thinning before they occur.

Fully Autonomous

The AI-driven system requires no manual intervention during production.

Quick Deployment

The system can be installed and fully operational within two weeks — one week for setup and one week for training and handover.

Die-Independent and Compatible

Works with all press types and doesn't rely on specific die setups, offering flexibility and lower integration costs.

Real-World Results: Automotive OEM Press Shop

During a proof-of-concept trial at a major automotive OEM factory, Digiforming's AI-based real-time control system successfully identified quality risks caused by process fluctuations. Its accurate defect predictions allowed the team to take timely action and avoid defects before they occurred. All without requiring any modifications to existing tooling.

Discover Your Real Costs

Do you know how much money you're losing in your production process? Learn the savings our defect prevention solution can provide with our ROI calculator.

Calculate NowOur AI-Driven Solutions Ecosystem

Digiforming delivers solutions for your biggest challenges.

Predicts serious damages that may occur in press or die during production and prevents unplanned downtime.

Leverages advanced high‐precision vision systems to automatically detect all defective parts at the end of the production line.

Q4 2025

Instantly detect leakages with a wireless IoT solution that monitors gas spring pressure values in real-time.