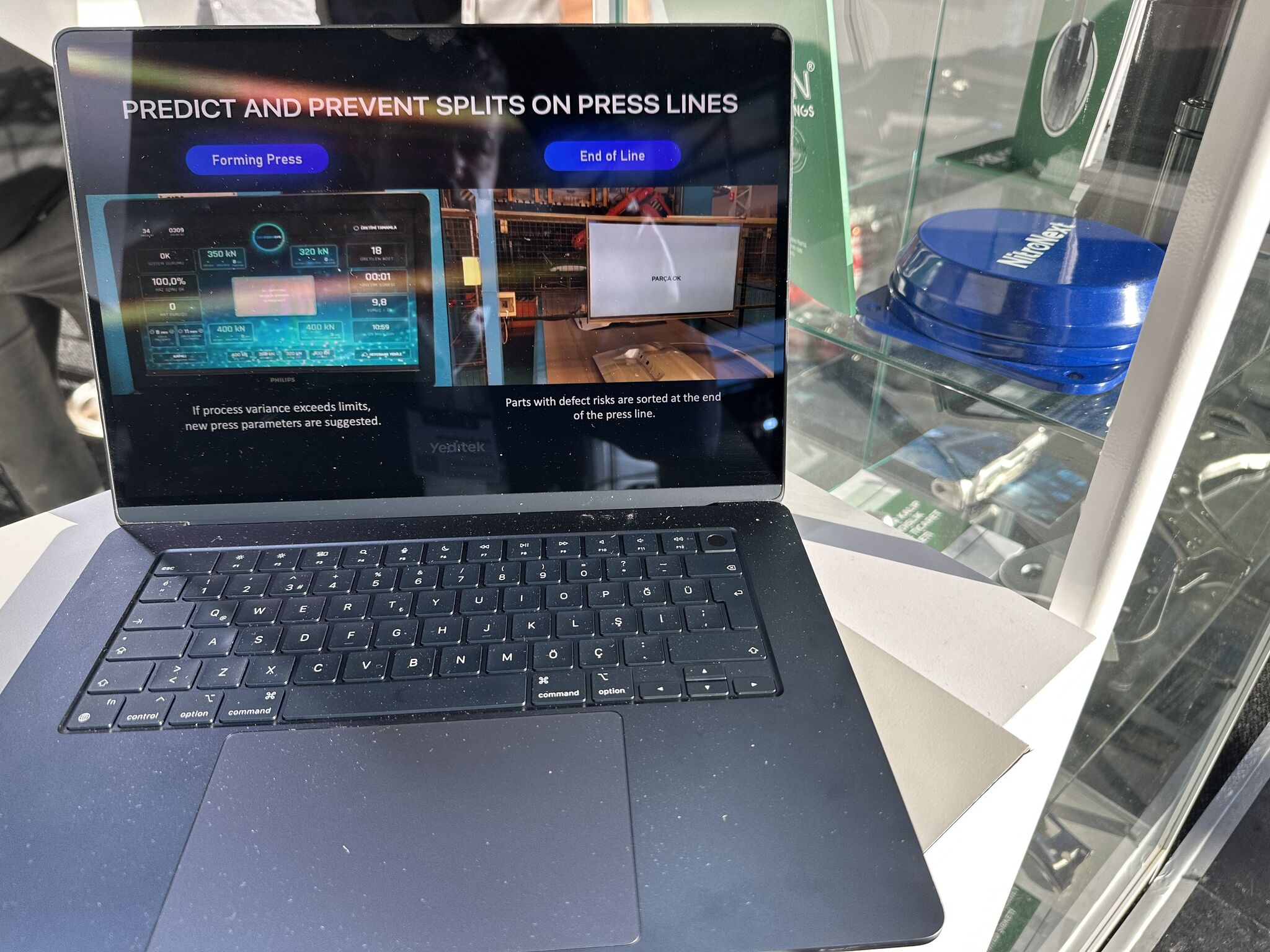

Smarter and Safer Stamping with AI-Driven Solutions

Our solutions boost quality and efficiency in press shops for sustainable operational advantage.

QUALITY

Scrap Rates

Customer Complaints

Reworks

EFFICIENCY

OEE & Production Speed

Unexpected Downtimes

Tool Lifespan

COMPETITIVENESS

Material Waste

Sustainability

Energy Costs

Our AI-Driven Solutions Ecosystem

Digiforming delivers solutions for your biggest challenges.

Latest Updates

Stay informed about our latest milestones, product updates and highlights from industry events.

Our CES 2025 Showcase

We introduced our breakthrough sheet metal forming technologies to a global audience, gaining attention from key industry players and innovation-focused investors.

Big Success at Big Bang 2024

At İTÜ Çekirdek Big Bang 2024, Digiforming was awarded for its innovation in sheet metal forming, gaining wide exposure and valuable industry connections.

Showcased at IAEC 2024

We showcased Digiforming Defect Prevention solution at the International Automotive Engineering Conference, where our innovative solutions were well received by industry professionals.

Global Debut at EuroBLECH 2024

We introduced Digiforming at one of the world's leading sheet metal forming fairs. It was our first international exhibition, a great opportunity to present our solution, connect with global manufacturers and benchmark competing technologies.

Award-Winning Innovation at the Future of Automotive Design Competition

Digiforming was recognized as one of the top innovations among 392 entries, earning praise from industry experts for its forward-thinking approach to sheet metal forming.

Top 10 Finalist at the Bilişim Vadisi Mobility Acceleration Program

Selected from 850 applicants, we proudly presented Digiforming at Demo Day, earning strong interest for our AI-powered defect prevention technology in sheet metal forming.