Digiforming Damage Prevention

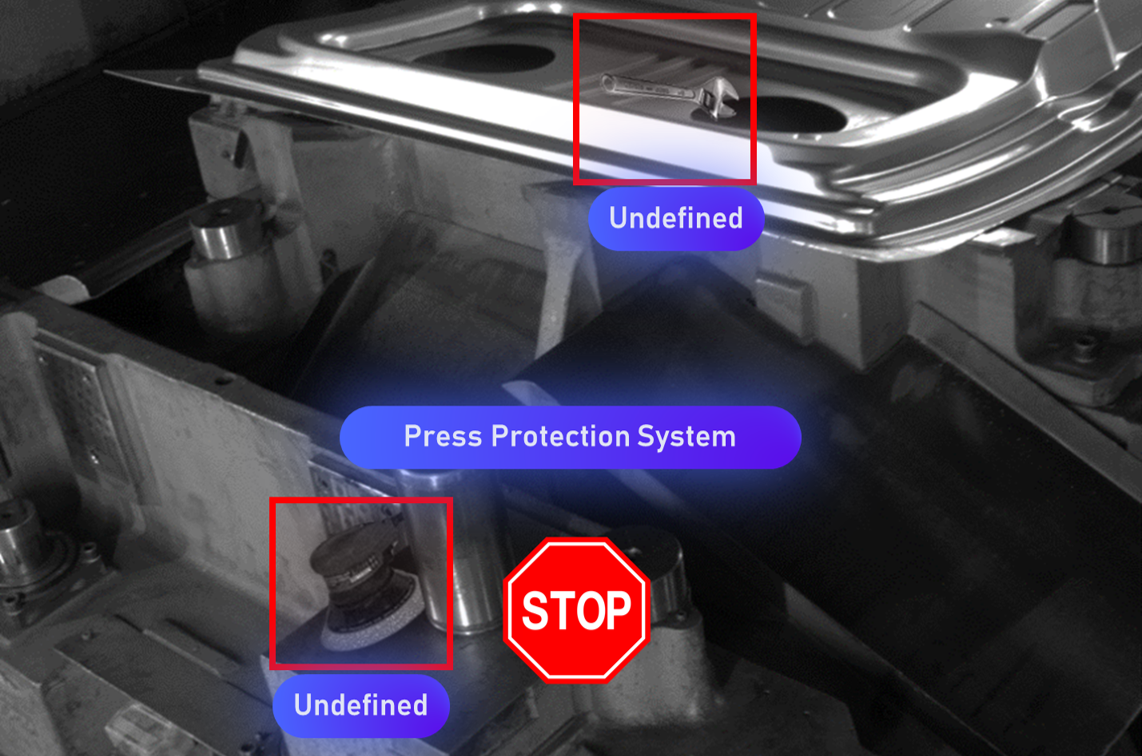

Our damage prevention system monitors production in real time to detect anomalies that could lead to tool or machine damage, enabling timely interventions to protect critical equipment.

Key Benefits

Prevents Costly Equipment Damage

Instantly detects foreign objects in the die area and stops the press to avoid damage worth €20K–€100K+ and up to 4 months of downtime.

Minimizes Unexpected Downtime

Prevents 1–4 weeks of unplanned downtime by eliminating undetected tool or press malfunctions during stamping operations.

Stops Press Instantly

Reacts immediately before the press closes, stopping the stroke to safeguard critical components.

No Extra Equipment Needed

Works seamlessly with the Digiforming system and requires no additional sensors or camera setups.

Protects Both Tool & Press

Prevents damage to both the die and press equipment, avoiding major production and financial setbacks.

Highly Reliable AI System

Built on years of R&D and robust trials, offering industrial-grade reliability and precision.

Looking for peace of mind in your press operations?

Request a demo to discover how our solution minimizes risks and protects your equipment.

Our AI-Driven Solutions Ecosystem

Digiforming delivers solutions for your biggest challenges.

Engineered for zero-defect autonomous stamping, Digiforming predicts and corrects process variations before defects occur.

Leverages advanced high‐precision vision systems to automatically detect all defective parts at the end of the production line.

Q4 2025

Instantly detect leakages with a wireless IoT solution that monitors gas spring pressure values in real-time.